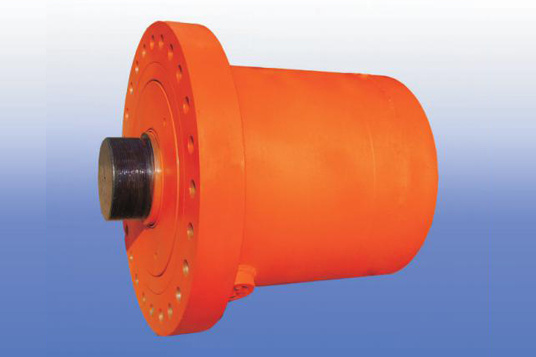

Cylinder

Tel: +86-0510-8395 9581

Cylinder

Unlike non-standard oil cylinders, cylindrical metal components guide the piston to move linearly back and forth in the cylinder. Air is converted into mechanical energy through expansion within the engine cylinder, and gas is compressed by the piston in the compressor cylinder, thereby increasing pressure. The cavity of the piston is placed on the cylinder body of the internal combustion engine. SMC and CM2 cylinder pistons use a combination sealing ring to achieve bidirectional sealing, and the piston is connected to the piston rod using a press-fit, without the need for nuts. The cylinder end cap is equipped with intake and exhaust ports, and some end caps also have a buffering mechanism. The rod side end cap is equipped with a sealing ring and a dust ring to prevent air leakage from the piston rod and dust from entering the cylinder from the outside. A guide sleeve is installed on the piston rod side cover to improve the guiding accuracy of the cylinder, bearing a small amount of lateral load on the piston rod, reducing downward bending when the piston rod is extended, and extending the service life of the cylinder. The guide sleeve is usually made of sintered oil-containing alloy and forward-leaning copper castings. In the past, ductile cast iron was commonly used for end caps. To reduce weight and prevent rust, aluminum alloy die-castings are often used, and miniature cylinders use brass materials.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Finished Pipe Drawing Thickness (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Related

Message