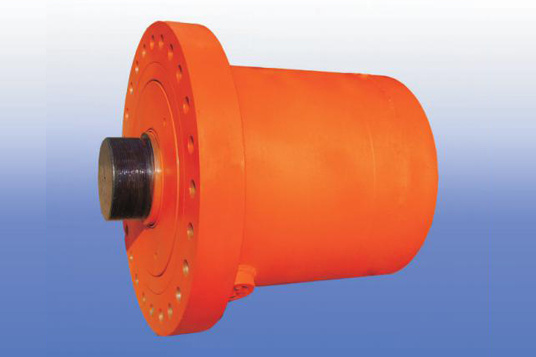

Cylinder

Unlike non-standard oil cylinders, the piston is a pressure component in the cylinder. The piston sealing rings are arranged to prevent the two sides of the piston from crossing each other. The wear-resistant rings on the piston can improve the guiding performance of the cylinder, reduce the wear of the piston sealing rings, and lower friction resistance. The wear-resistant rings are made of materials such as polyurethane, polytetrafluoroethylene, and synthetic resin. The width of the piston is determined by the size of the sealing ring and the length of the necessary sliding components. If the sliding components are too short, it will not cause early wear and spasms. The piston material is usually made of aluminum alloy and cast iron, while small cylinder pistons are made of brass.

In pneumatic transmission, the pressure of compressed gas can be converted into mechanical energy by pneumatic actuators. There are two types of cylinders: reciprocating linear motion and reciprocating swinging. Reciprocating linear motion cylinders can be divided into four types: single-acting cylinders, double-acting cylinders, and diaphragm cylinders.

1. Single-acting cylinder: There is a piston rod only on one end. The gas collected from one side of the piston generates air pressure. The air pressure pushes the piston to generate thrust, and then it returns through a spring or its own weight.

2. Double-acting cylinder: Air is supplied alternately from both sides of the piston, outputting force in one or both directions.

3. Diaphragm cylinder: Uses a diaphragm instead of a piston, outputting force in only one direction, with spring reset. It has good sealing performance but a short stroke.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Related

Message