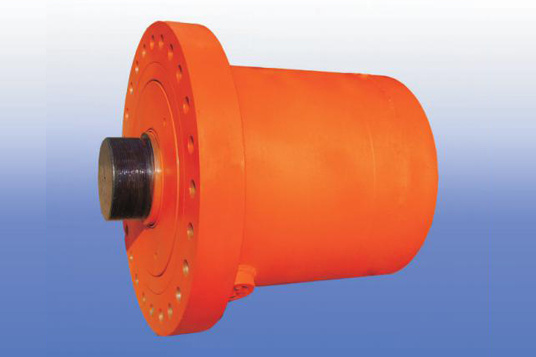

Oil cylinder

The output force of a non-standard hydraulic cylinder is proportional to the effective area of the piston and the pressure difference on both sides; a hydraulic cylinder is mainly composed of a cylinder body and cylinder head, piston and piston rod, sealing device, buffering device, and exhaust device. The buffering device and exhaust device depend on specific applications, while other components are essential. Non-standard hydraulic cylinders are actuators in hydraulic transmission systems. They are energy conversion devices that convert hydraulic energy into mechanical energy. Hydraulic motors achieve continuous rotary motion, while hydraulic cylinders achieve reciprocating motion. There are three structures of hydraulic cylinders: piston cylinders, plunger cylinders, and swing cylinders. Hydraulic cylinders are actuators in hydraulic transmission systems. They are energy conversion devices that convert hydraulic energy into mechanical energy. Hydraulic motors achieve continuous rotary motion, while hydraulic cylinders achieve reciprocating motion. The structure of hydraulic cylinders includes piston cylinders, plunger cylinders, and swing cylinders. Piston cylinders and plunger cylinders achieve reciprocating linear motion, output speed and thrust, while swing cylinders achieve reciprocating swinging motion, output angular speed (velocity) and torque. Besides single-use, hydraulic cylinders can also be combined with two or more other mechanisms to perform special functions. The structure of hydraulic cylinders is simple and reliable. They have been widely used in hydraulic systems of machine tools. According to structural form, they can be divided into piston type, plunger type, multi-stage telescopic type, gear rack type, etc.; according to installation form, they can be divided into pull rod, ear ring, foot, hinge shaft, etc.; pressure levels can be divided into 16MPa, 25MPa, 31.5Mpa, etc.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Finished Pipe Drawing Thickness (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Hydraulic Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message