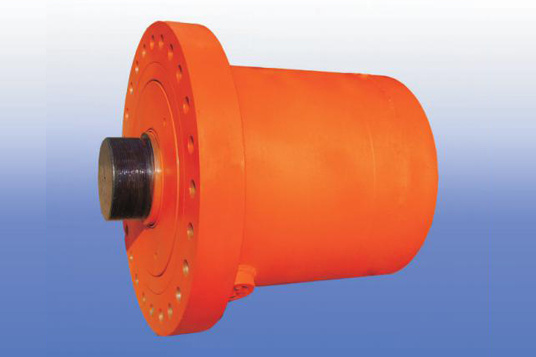

Oil cylinder

The telescopic non-standard hydraulic cylinder has two or more multi-stage pistons. The order of the pistons in the telescopic hydraulic cylinder is from large to small, while the order of the empty return is generally from small to large. The telescopic cylinder can achieve a longer stroke with a shorter retraction length and a more compact structure. This type of hydraulic cylinder is often used in construction machinery and agricultural machinery. When the piston moves once or multiple times, the output speed and output force of the piston change as the pistons move successively.

The main reasons for scratches on the inner surface of the cylinder are as follows:

When measuring the inner diameter of the cylinder body with an internal micrometer, insert the measuring contact with a friction edge into the inner wall of the cylinder body. The measuring contact is made of high hardness and wear-resistant hard alloy. Generally, minor scratches from shallow measurements do not affect operational accuracy. However, if the size of the measuring rod tip is improperly adjusted, the rigid insertion of the measuring contact will cause more severe scratches. To solve this problem, the first step is to measure the length of the adjustable measuring head. Additionally, a measuring tape with only one hole for the measuring position can be attached to the inner surface of the cylinder wall, which will not produce the aforementioned shape of scratches. Minor scratches caused by measurement can be wiped off with the back of old sandpaper or horse manure paper.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

Number of System Stations (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message