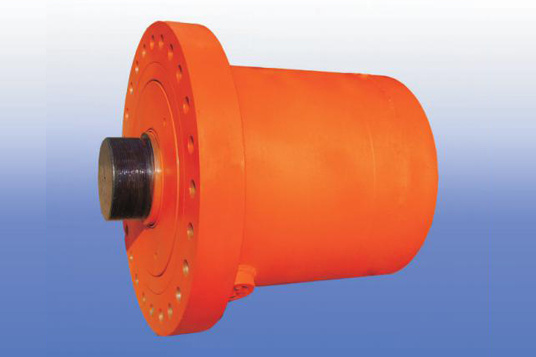

Piston rod

The stainless steel piston rod is mainly used for hydraulic and pneumatic systems, engineering machinery, and piston rods in automobile manufacturing. Due to the surface residual compressive stress on the piston rod, it helps seal small cracks on the surface and hinders the expansion of erosion. Therefore, it can improve surface corrosion resistance, delay or expand fatigue cracks, thus enhancing the fatigue strength of the cylinder rod. The piston rod is a connecting component that supports the operation of the piston. It is mainly used in the motion execution parts of cylinders and pistons. It is a frequently moving component with high technical requirements. Taking hydraulic cylinders as an example, it consists of a cylinder, piston rod (cylinder rod), piston, and end cap. The processing quality directly affects the lifespan and reliability of the entire product. The processing requirements for piston rods are high, with a surface roughness of Ra 0.4-0.8 microns, and strict requirements for coaxiality and wear resistance. The basic characteristic of cylindrical rods is the processing of slender shafts, which is difficult and has always troubled processing enterprises. The applications of piston rod products include: piston rods are mainly used in hydraulic and pneumatic systems, engineering machinery, automobile manufacturing piston rods, plastic machinery supports, packaging machinery, printing machinery rollers, textile machinery, conveying machinery shafts, and linear optical axes for linear motion.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Finished Pipe Drawing Thickness (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Previous

Related

Message