Precision piston rod quotation

The precision piston rod is formed through rolling, creating a layer of cold-worked hardened layer on the rolling surface, which reduces the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the cylinder rod surface and avoiding burns caused by grinding. After rolling, the reduction in surface roughness can enhance matching performance. The processing of the piston rod requires high precision, with a surface roughness requirement of Ra0.4 to 0.8μm, and strict requirements for coaxiality and wear resistance. The piston rod is formed by rolling, creating a cold-worked hardened layer on the rolling surface, which reduces the elastic-plastic deformation of the grinding contact surface, thereby improving the wear resistance of the cylinder rod surface and avoiding burns caused by grinding.

Function of the Piston Rod:

The function of the piston rod is to connect the piston and the crosshead, transmitting the force acting on the piston and driving the piston movement.

Basic Requirements for the Piston Rod:

(1) Sufficient strength, stiffness, and stability;

(2) Good wear resistance, high processing accuracy, and high surface roughness requirements;

(3) Minimize the impact of structural stress concentration;

(4) Reliable connection to prevent loosening;

(5) The design of the piston rod structure facilitates the disassembly and assembly of the piston.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

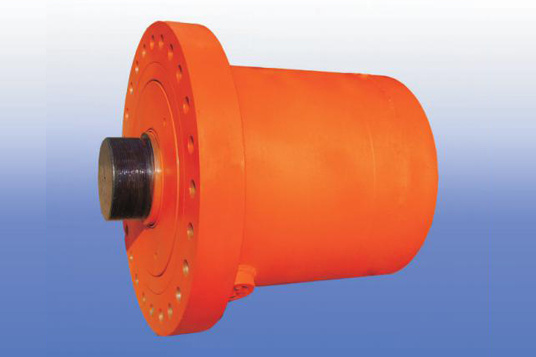

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

Number of System Stations (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Overall Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message