Cold drawn pipe

In the production process, cold drawn pipes are usually quenched and heated using a high-temperature salt bath furnace to achieve deoxidation. However, during implementation, cold drawn pipes cannot be completely deoxidized. When subjected to cold carbon erosion, cold drawn pipes may exhibit insufficient hardness. The cooling rate during the quenching process also significantly affects the hardness of cold drawn pipes. Generally, the slower the cooling speed, the lower the product hardness. To prevent this situation, it is necessary to strictly restore the salt bath and control the cooling temperature and time to achieve the best product.

The hardening of cold drawn pipes is precise. During the cold drawing process, the metal undergoes plastic deformation. There are many slip systems in the crystal. Dislocation movements intercept each other. Many dislocations are pinned, leading to dislocation accumulation and the cessation of dislocation sources. These processes result in a reduced dislocation mobility and a significant increase in dislocation density within the crystal. When further plastic deformation occurs, the stress increases enough to cause pinned dislocations to start moving, leading to the crossing and sliding of screw dislocations, while edge dislocations cannot cross and slide, resulting in dislocation crossing and an increase in the fixed order. Therefore, by increasing dislocation density and reducing dislocation mobility during the cold drawing process, the hardness and strength of the metal material are improved, making the generation and movement of dislocations more difficult. This is the metallurgical principle of cold drawing.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Tension (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

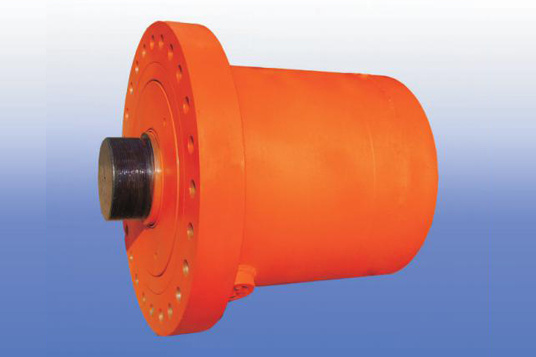

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Piston Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message