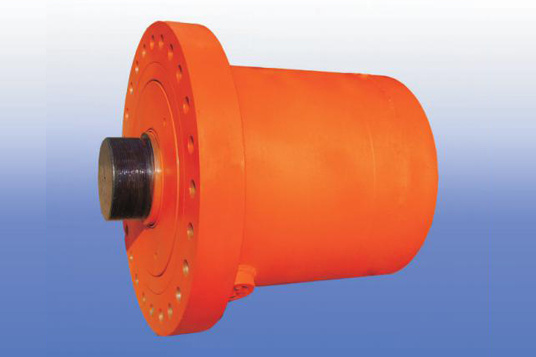

Piston rod

Tel: +86-0510-8395 9581

Piston rod

The precision piston rod is processed through rolling, which improves the surface's corrosion resistance, delays the occurrence or expansion of fatigue cracks, and thus enhances the fatigue strength of the cylinder rod. Through rolling, a layer of cold-work hardened layer is formed on the rolling surface, reducing the elastic and plastic deformation of the grinding contact surface, thereby improving the wear resistance of the cylinder rod surface and avoiding burns caused by grinding. After rolling, the reduction in surface roughness can enhance matching performance. At the same time, when the piston rod moves, the friction damage of the sealing ring or seal is reduced, thus extending the overall service life of the oil cylinder. Rolling technology is an efficient and high-quality technical means. The processing technology of the piston rod is also an important component of the piston rod. The processing technology of the piston rod directly affects the quality and service life of the piston rod. Rolling processing is generally used for the processing of piston rods because this processing method can improve the corrosion resistance of the piston rod surface, delay the occurrence and expansion of fatigue cracks, and thus enhance the fatigue strength of the piston rod.

|

Φ6

|

Φ8

|

Φ10

|

Φ12

|

Φ16

|

Φ20

|

Φ22

|

Φ25

|

Φ28

|

Φ30

|

Φ32

|

Φ35

|

|

Φ36

|

Φ38

|

Φ40

|

Φ45

|

Φ50

|

Φ55

|

Φ60

|

Φ65

|

Φ70

|

Φ75

|

Φ80

|

Φ85

|

|

Φ90

|

Φ100

|

Φ105

|

Φ110

|

Φ120

|

Φ125

|

Φ130

|

Φ 140

|

Φ150

|

Φ160

|

Φ170

|

Φ180

|

|

Φ200

|

Φ220

|

ф250

|

ф300

|

Φ350

|

Φ400

|

Φ450

|

Φ500

|

Φ550

|

Φ600

|

Φ650

|

ф700-ф1600

|

Product Parameters

|

Model

|

JLB150T

|

JLB250T

|

JLB300T

|

JLB400T

|

JLB600T

|

JLB1000T

|

|

|

Maximum Tension (KN) |

1630

|

2700

|

3200

|

4100

|

6500

|

12000

|

|

|

Drawing Speed (M/min) |

0-5.5

|

0-4.5

|

0-4.5

|

0-4

|

0-3

|

0-3

|

|

|

Effective Length of Finished Pipe (M) |

1.5-10

|

1.5-10

|

1.5-10

|

1.5-10

|

1.5-10

|

1.5-10

|

|

|

Finished Pipe Drawing Thickness (mm) |

20

|

25

|

30

|

33

|

42

|

70

|

|

|

Main Oil Cylinder (mm) |

Φ320/Φ 150x10000

|

Φ420/Φ 210x10000

|

Φ450/Φ 210x10000

|

Φ500/Φ 220x10000

|

Φ630/Φ 280x10000

|

Φ850/Φ 350x10000

|

|

|

System Station Count (Station) |

2

|

2

|

2

|

2

|

2

|

2

|

|

|

System Working Pressure (Mpa) |

26

|

26

|

26

|

26

|

26

|

26

|

|

|

System Maximum Pressure (Mpa) |

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

|

|

Pump (Manual Variable Plunger Pump) |

160Lx3

|

160Lx2 250Lx1

|

250Lx3

|

250Lx3

|

250Lx3

|

400Lx3

|

|

|

Main Motor (KW) |

55x3

|

55x2 75x3

|

75x3

|

75x2 90x1

|

90x3

|

132x3

|

|

|

Dimensions (WxHxL)

|

1.6x1.4x42

|

1.7x1.5x44

|

1.7x1.5x44

|

1.9x1.8x45

|

2.1x2x45

|

2.65x2.65x60

|

|

|

Weight (T) |

86

|

100

|

120

|

180

|

220

|

300

|

|

Previous

Next

Previous

Next

Related

Message