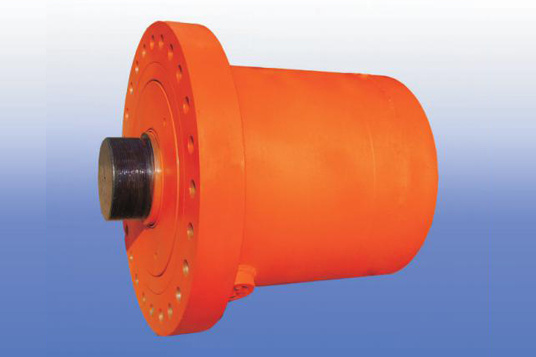

Piston rod

The piston rod has sufficient strength, rigidity, and stability, with good wear resistance, high processing accuracy, and high surface roughness requirements; efforts should be made to minimize the impact of structural stress concentration; connections should be reliable to prevent loosening; the design of the piston rod structure should facilitate the disassembly of the piston. The main function of the piston rod packing ring is to seal the gap between the cylinder seat and the piston rod, preventing leakage of the piston rod. In the piston rod packing, there are generally three gaps: axial gap: mainly used to ensure that the packing ring can float freely; otherwise, the piston rod cannot work properly. Radial gap: prevents the piston rod from sinking and compressing the packing ring, avoiding deformation or damage. Causes of piston rod overheating:

(1) When the piston rod and packing are assembled, they are misaligned and cause local friction. They should be adjusted in time.

(2) The tension spring of the sealing ring is too tight, and the friction force should be adjusted appropriately.

(3) The axial gap of the sealing ring is too small, and the axial gap should be adjusted according to requirements.

(4) If the oil quantity is insufficient, it should be increased appropriately.

(5) The piston rod and sealing ring do not operate smoothly, and the break-in process should be strengthened during research.

(6) Impurities are mixed in the gas and oil, and cleaning should be performed to keep it clean.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

Number of System Stations (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

Maximum System Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Piston Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message