Hydraulic Cold Drawing Machine

Tel: +86-0510-8395 9581

Hydraulic Cold Drawing Machine

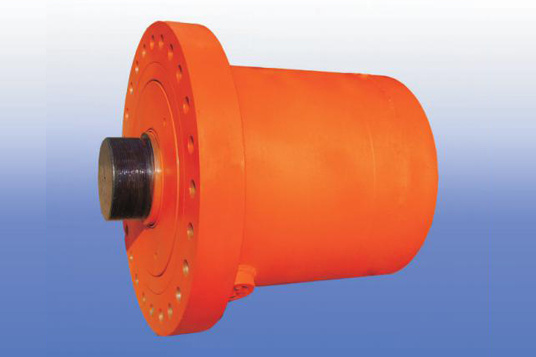

The precision hydraulic cold drawing machine first inserts the core rod into the inner hole of the pipe when drawing steel pipes, then places the core body, and pushes out the front end of the steel pipe that has been threaded onto the core. Start the pre-tightening oil cylinder to clamp the steel pipe and pull the car to the starting position. The main oil cylinder begins to draw out. At the same time, the gas cylinder is pulled out, the end of the steel pipe is released, and the finished pipe is pulled out from the valve body. The slider moves in the opposite direction, allowing the plug to be quickly pulled out from the pipe, facilitating the punching process. When using the cold drawing machine to draw steel pipes, first place the core rod into the inner hole of the pipe, then install the core rod head, and push out the front end of the steel pipe that has been placed on the core rod head to the drawing die seat. Start the pre-tightening cylinder to clamp the steel pipe with the plate teeth, and the traction vehicle is in the starting position, and the main cylinder begins to pull. At the end of the drawing, the pre-tightening cylinder moves, the plate teeth release the steel pipe fork, and the finished pipe is pushed out of the vehicle body. The slider moves in the opposite direction, allowing the plug to quickly exit the pipe, ensuring smooth unloading. In the 1990s, with the continuous in-depth research and application of cold drawn steel pipe technology in China, cold drawn steel pipe technology has been widely used in the manufacturing of hydraulic cylinders and oil cylinders for engineering machinery. The cold drawing machine is the main processing equipment for cold drawn steel pipes, used for cold drawing black and non-ferrous metal bars at room temperature, as well as secondary processing of waste steel pipes after hot rolling and extrusion. It is used to produce small diameter pipes, precision, thin-walled, and high mechanical performance main pipeline processing equipment.

Product Parameters

|

Model

|

JLB150T

|

JLB250T

|

JLB300T

|

JLB400T

|

JLB600T

|

JLB1000T

|

|

|

Maximum Pulling Force (KN) |

1630

|

2700

|

3200

|

4100

|

6500

|

12000

|

|

|

Drawing Speed (M/min) |

0-5.5

|

0-4.5

|

0-4.5

|

0-4

|

0-3

|

0-3

|

|

|

Effective Length of Finished Pipe (M) |

1.5-10

|

1.5-10

|

1.5-10

|

1.5-10

|

1.5-10

|

1.5-10

|

|

|

Thickness of Finished Pipe (mm) |

20

|

25

|

30

|

33

|

42

|

70

|

|

|

Main Oil Cylinder (mm) |

Φ320/Φ 150x10000

|

Φ420/Φ 210x10000

|

Φ450/Φ 210x10000

|

Φ500/Φ 220x10000

|

Φ630/Φ 280x10000

|

Φ850/Φ 350x10000

|

|

|

Number of System Stations (Station) |

2

|

2

|

2

|

2

|

2

|

2

|

|

|

System Working Pressure (Mpa) |

26

|

26

|

26

|

26

|

26

|

26

|

|

|

System Maximum Pressure (Mpa) |

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

31.5

|

|

|

Pump (Manual Variable Piston Pump) |

160Lx3

|

160Lx2 250Lx1

|

250Lx3

|

250Lx3

|

250Lx3

|

400Lx3

|

|

|

Main Motor (KW) |

55x3

|

55x2 75x3

|

75x3

|

75x2 90x1

|

90x3

|

132x3

|

|

|

Dimensions (WxHxL)

|

1.6x1.4x42

|

1.7x1.5x44

|

1.7x1.5x44

|

1.9x1.8x45

|

2.1x2x45

|

2.65x2.65x60

|

|

|

Weight (T) |

86

|

100

|

120

|

180

|

220

|

300

|

|

Previous

Next

Previous

Next

Related

Message