Cold drawn pipe

The advantages of cold drawn pipes include no oxidation layer on the inner and outer walls; high pressure resistance without leakage; high precision; high surface finish; no deformation during cold bending; expansion, flattening, and no cracks. It can be seen that the requirements for the inner diameter, outer wall dimensions, and roughness of precision cold drawn pipes are high to adapt to various applications. Through practice, it has been found that this product performs exceptionally well in applications and is an ideal pipe material. During the cold drawing process, the steel pipe undergoes plastic deformation under the action of force in molds of certain shapes and sizes. Currently, the drawing methods in production can be roughly divided into three types: diameter reduction drawing, outer wall diameter reduction drawing, and inner wall diameter reduction drawing. During the cold drawing process, the steel pipe undergoes corresponding deformation under the action of drawing force, positive pressure, and friction, mainly experiencing three stages: diameter reduction, wall thinning, and sizing, with corresponding stresses occurring in the deformation zone where axial stress is tensile stress, and radial and circumferential stresses are compressive stresses. The metal is in a state of unidirectional tensile and bidirectional compressive stress during the drawing process, which is the basic mechanical characteristic of the cold drawing process.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

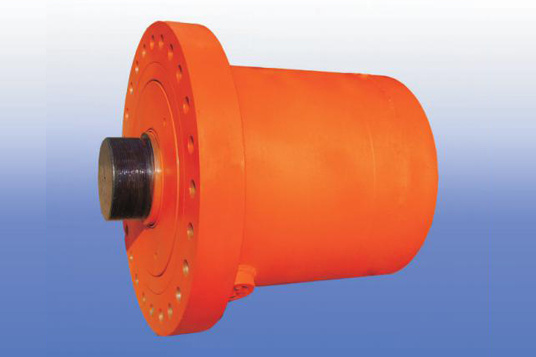

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

Number of System Stations (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Piston Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Overall Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message