Honing tube

The basic characteristics of the honing pipe produced by the honing machine are to eliminate the processing hardening and accumulated cold deformation before cold deformation to a certain extent. A series of preparatory work should be carried out to eliminate hardened workpieces and other needs. Cold deformation is necessary, the process is complex, and the pipe material usually undergoes a large amount of cold deformation from production to finished product. Moreover, the entire production process often includes many production cycles, including preparation and deformation processes, cycle periods, long production cycles, large metal consumption, and most equipment is arranged in a single row, generally not produced continuously. The support bushing is set in the groove of the inner diameter of the guide sleeve, providing guidance and support for the piston rod. The reasonable design gap between the inner and outer diameters of the piston rod is 0.08-0.16mm. When the gap is greater than 0.16mm, the piston rod is prone to eccentric wear, and the bushing is pressed to one side, leading to oil leakage between the honing cylinder and the piston rod. The outer diameter of the support bushing contacts the inner diameter of the honing cylinder, and the reasonable design gap is 0.1-0.19mm. When the piston rod is less than 0.1mm, the resistance to the movement of the piston rod increases, and the piston rod cannot maintain uniform motion. The bushing cannot provide support, and the baffle or outer edge of the piston on the piston rod is prone to scratch the inner wall of the cylinder, which can lead to cylinder scrapping in severe cases. Therefore, the assembly gap is crucial to the quality of the honing cylinder.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Pulling Force (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Thickness of Finished Pipe (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

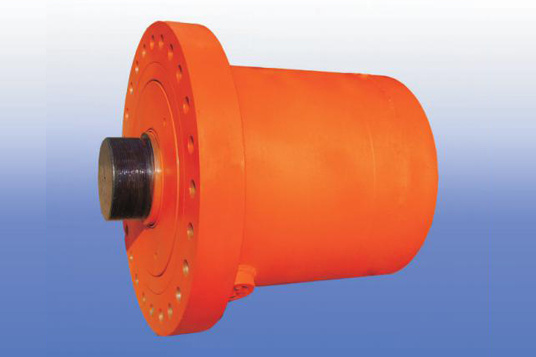

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

Number of System Stations (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

Maximum System Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (Manual Variable Plunger Pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message