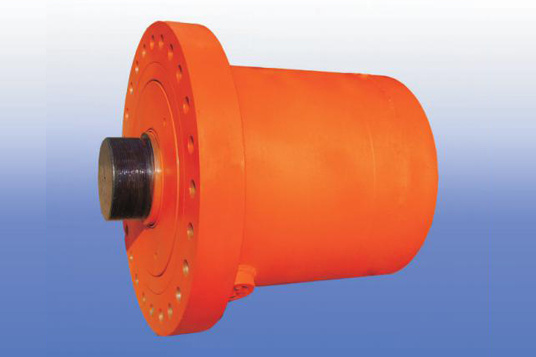

Roller pipe

The rolled pipe has the following advantages compared to traditional honed pipes:

(1) Improved processing efficiency: The processing speed is almost twenty times that of honing.

(2) Improved surface hardness: Surface hardness increases by more than 50%.

(3) Processing accuracy: Processing accuracy can reach IT8 level, and surface roughness can reach Ra0.05-0.4m.

(4) Working environment: Low noise, no pollution, saves labor costs.

(5) Reasonable processing technology: The scraping roller can serve as the final process for other operations (such as drilling, welding, turning, etc.).

What is a rolled pipe? I believe many people are not very familiar with it. In fact, it is a type of cold-rolled or hot-rolled pipe. In the production of pipes, the pipe needs to be bent first, and then it is made into a square pipe through high-frequency welding. However, if one wants to produce hydraulic rolled pipes with better corrosion resistance, the staff also needs to form cold-formed hollow square pipes for hot-dip galvanizing treatment. Since galvanizing greatly improves the corrosion resistance of square pipes, it extends the service life of square pipes. Using this hydraulic rolled pipe is very common in both steel construction projects and industries such as machinery manufacturing. According to relevant personnel from the towel folding machine manufacturer, additionally, using this hydraulic rolled pipe is also essential for the production of solar brackets.

Product Parameters

Model | JLB150T | JLB250T | JLB300T | JLB400T | JLB600T | JLB1000T | |

Maximum Tension (KN) | 1630 | 2700 | 3200 | 4100 | 6500 | 12000 | |

Drawing Speed (M/min) | 0-5.5 | 0-4.5 | 0-4.5 | 0-4 | 0-3 | 0-3 | |

Effective Length of Finished Pipe (M) | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | 1.5-10 | |

Finished Pipe Drawing Thickness (mm) | 20 | 25 | 30 | 33 | 42 | 70 | |

Main Oil Cylinder (mm) | Φ320/Φ 150x10000 | Φ420/Φ 210x10000 | Φ450/Φ 210x10000 | Φ500/Φ 220x10000 | Φ630/Φ 280x10000 | Φ850/Φ 350x10000 | |

System Station Count (Station) | 2 | 2 | 2 | 2 | 2 | 2 | |

System Working Pressure (Mpa) | 26 | 26 | 26 | 26 | 26 | 26 | |

System Maximum Pressure (Mpa) | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |

Pump (manual variable plunger pump) | 160Lx3 | 160Lx2 250Lx1 | 250Lx3 | 250Lx3 | 250Lx3 | 400Lx3 | |

Main Motor (KW) | 55x3 | 55x2 75x3 | 75x3 | 75x2 90x1 | 90x3 | 132x3 | |

Dimensions (WxHxL) | 1.6x1.4x42 | 1.7x1.5x44 | 1.7x1.5x44 | 1.9x1.8x45 | 2.1x2x45 | 2.65x2.65x60 | |

Weight (T) | 86 | 100 | 120 | 180 | 220 | 300 | |

Previous

Next

Previous

Next

Related

Message